用途事例

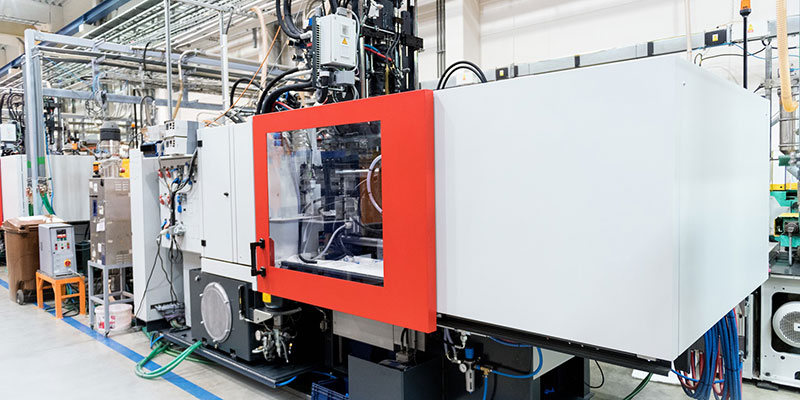

Molding Processing

Generally, various molded products made from resins and plastics is manufactured in a clean room. In particular, strict quality control is required for molded products for medical equipment, food products, and automotive products. In the molding processing, packaging, and inspection processes, it is also necessary to monitor relatively large particles of several tens of microns in size, since the adhesion of foreign matter (contamination) directly affects product quality.

Particle Sensing Monitor can be installed in multiple locations and networked to collectively manage the air cleanliness of each process and trends in the increase or decrease of foreign matter. In addition, continuous monitoring can minimize production loss in the event of an abnormality. By connecting an optional temperature and humidity sensor, simultaneous monitoring of temperature and humidity, which affect molding quality, is also possible.